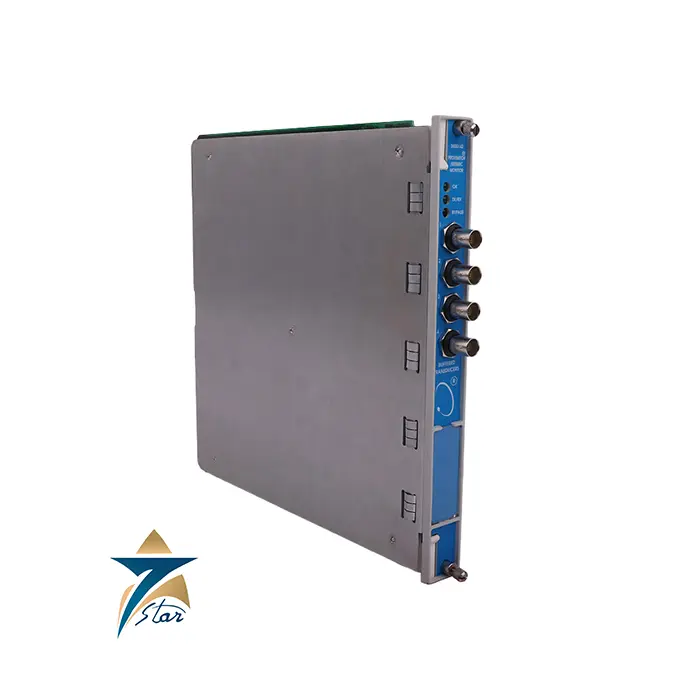

Bently Nevada 3500/42M Proximitor Seismic Monitor

Overview

The Bently Nevada 3500/42M Proximitor Seismic Monitor is a key monitoring component within the 3500 Machinery Protection System family. This module accepts input from up to four proximity and seismic transducers, conditions incoming signals to produce vibration, position, and other diagnostic measurements, and then compares these values with user-configurable alarm thresholds to assist in proactive machine protection and performance evaluation.

Designed for continuous industrial operation, the 3500/42M is widely used in heavy machinery applications where reliable real-time condition data is crucial for minimizing unplanned downtime and maximizing asset life. Its flexible programming allows machine operators and maintenance personnel to tailor alarm logic to specific machine behavior and performance criteria.

Key Features & Functionality

The 3500/42M monitor provides a robust set of features for condition monitoring and machinery protection:

-

Four independent monitoring channels for proximitor and seismic transducers.

-

Conditioning of vibration, position, and seismic inputs into static values for meaningful analysis.

-

User-programmable alarm setpoints for ALERT and DANGER thresholds to support proactive maintenance strategies.

-

Integration with Bently Nevada’s 3500 Rack Configuration Software to configure measurement modes and alarm responses.

-

Compact design for straightforward rack installation within larger monitoring systems.

This combination of functionality makes the 3500/42M an excellent choice for protecting critical rotating machinery across industrial sectors.

Industrial Applications

The 3500/42M Proximitor Seismic Monitor is used extensively in condition monitoring and machine protection programs across key industries, including:

-

Power generation plants for turbine and generator monitoring.

-

Oil & gas and petrochemical facilities with rotating equipment needing reliable alarm logic.

-

Heavy industrial manufacturing where machine vibration and position data inform maintenance decisions.

By providing early warning of abnormal vibration or position changes, the monitor helps operators and maintenance teams prevent catastrophic failures and optimize maintenance scheduling.

Installation & Integration

The Bently Nevada 3500/42M monitor is designed for installation within a 3500 Series rack environment. It interfaces with proximity probes, seismic sensors, extension cables, and channeled I/O wiring. Using the 3500 Rack Configuration Software, technicians can program and tune alarm thresholds, measurement functions, and channel configurations to suit specific machinery protection needs.

Because it forms part of a modular system, the monitor integrates with other 3500 modules and machinery protection infrastructure to deliver a scalable condition monitoring solution.

FAQ

What is the Bently Nevada 3500/42M monitor used for?

It is used to measure and condition vibration and position signals from proximity and seismic transducers, and compare them with alarm setpoints for machine protection.

How many channels does the 3500/42M support?

It supports four independent channels for monitoring.

Can it monitor both proximity and seismic sensors?

Yes — it accepts input from both proximity and seismic transducers.

Is the 3500/42M programmable?

Yes — channels can be configured via 3500 Rack Configuration Software to tailor alarm and measurement functions.

Call to Action

Request a quote for the Bently Nevada 3500/42M Proximitor Seismic Monitor and enhance your machine condition monitoring and protection systems. Contact Seven Star LLC for pricing, availability, and technical support.

Bently Nevada, a division of Baker Hughes, is a global leader in asset condition monitoring and protection technologies. For over six decades, the company has set the industry standard in machinery diagnostics, vibration analysis, and predictive maintenance solutions.

Its advanced systems and sensors are designed to ensure maximum equipment uptime, safety, and efficiency across power generation, oil & gas, and industrial manufacturing sectors. From vibration probes and monitoring racks to software platforms like System 1, Bently Nevada products enable real-time insight and data-driven decision-making.

Seven Star LLC supplies genuine Bently Nevada equipment, sensors, and monitoring solutions to clients across the Middle East, providing trusted reliability, expert support, and seamless integration for modern industrial operations.

Reviews

There are no reviews yet.