Blog

Dakota ZX Series Corrosion Gauge + Authorized Dealer in Oman

The Dakota ZX Series Corrosion Gauge.

Seven Star LLC is the authorized dealer of Dakota NDT in Oman, which means you’re getting the real deal with actual local support.

Seven Star LLC is pleased to announce our appointment as the sole authorized representative and distributor for Dakota Ultrasonics (Dakota NDT) in the Sultanate of Oman and Middle-East Region.

This partnership formally establishes Seven Star LLC as the first official and authorized Dakota NDT representative in the Middle East to source directly from the factory in the United Kingdom and CA, USA.

Why Choose Seven Star LLC for Dakota NDT?

Remote Support: Technical assistance is via phone or video call.

Direct Factory Supply: We guarantee direct supply of all genuine Dakota NDT Ultrasonic Thickness Gauges and NDT Equipment.

Competitive Pricing: Direct sourcing from the UK factory allows us to offer the most competitive pricing for Dakota products in the region.

Extended Warranty: Our Dakota NDT products come with industry-leading warranties, covering customers for up to five years.

The Dakota ZX Series Corrosion Gauge has become the go-to solution for industrial facilities across the Middle East, and for good reason. When you’re sourcing a Dakota ZX Series Corrosion Gauge from an authorized dealer in Oman, you’re not just buying measurement equipment – you’re investing in asset integrity and operational safety.

Let me break down why the Dakota ZX Series Corrosion Gauge matters to you, your team, and your bottom line.

Complete Product Portfolio: Dakota ZX Series Corrosion Gauge & NDT Equipment

Here’s your complete reference guide to all Dakota ZX Series Corrosion Gauge models and related NDT equipment available from Seven Star LLC, your authorized dealer in Oman:

| Product Name | Model | Key Features | Ideal Applications | Product Link |

|---|---|---|---|---|

| Dakota ZX1 Thickness Gauge | ZX-1 | Pre-calibrated for steel, 1.5-200mm range, basic measurements | Steel structures, pipes, tanks – entry-level corrosion monitoring | View ZX1 |

| Dakota ZX3 Thickness Gauge | ZX-3 | Extended range 0.63-914.4mm, high-speed scan mode, programmable velocities | Multi-material facilities, versatile measurements, pitting detection | View ZX3 |

| Dakota ZX5-DL Thickness Gauge | ZX-5DL | Data logging (10,000 readings), PC software included, trending analysis | Documentation-heavy operations, compliance reporting, trend analysis | View ZX5-DL |

| Dakota ZX6-DL Thickness Gauge | ZX-6DL | Through-paint (Echo-Echo) mode, data logging, dual measurement modes | Coated assets, CUI monitoring, advanced corrosion programs | View ZX6-DL |

Why Everyone’s Talking About Dakota ZX Series Corrosion Gauge in the Middle East

You know how sometimes a piece of equipment just… makes sense? The Dakota ZX Series Corrosion Gauge is one of those rare tools that combines simplicity with serious capability. It’s not trying to be everything to everyone – it’s laser-focused on doing corrosion monitoring exceptionally well.

Every Dakota ZX Series Corrosion Gauge model delivers professional-grade performance that procurement specialists and engineers across Oman have come to trust. The Dakota ZX Series Corrosion Gauge lineup represents years of ultrasonic technology refinement specifically for industrial corrosion applications.

Seven Star LLC’s partnership with Dakota NDT isn’t just some paper agreement. We’re the authorized sales and support representative for Dakota Ultrasonics across the entire Sultanate of Oman. This means when you buy a Dakota ZX Series Corrosion Gauge from us as your authorized dealer in Oman, you’re getting manufacturer-backed support, genuine calibration certificates, and access to the complete range of transducers and accessories designed specifically for the Dakota ZX Series Corrosion Gauge.

Here’s what makes this partnership different: we’re not just selling you a Dakota ZX Series Corrosion Gauge and wishing you luck. Our team actually understands the technical challenges you’re facing in Oman’s industrial environment – the heat, the humidity, the corrosion under insulation that keeps you up at night. We know the Dakota ZX Series Corrosion Gauge inside and out.

The Dakota ZX Family: Four Gauges, One Mission

Let’s talk about the lineup. Dakota offers four models in the ZX series, and each one builds on the previous model’s capabilities. Think of it like choosing the right tool for your specific job – you wouldn’t use a sledgehammer to hang a picture frame, right?

Dakota ZX1: The Straightforward Starter

The Dakota ZX1 is your entry point into professional thickness gauges. It comes pre-calibrated for steel, which means you literally take it out of the box and start measuring. No complex setup, no hours spent reading manuals.

Measurement range: 1.5 to 200mm (0.059 to 8 inches)

Resolution: 0.01mm

What it’s perfect for: Quick corrosion checks on steel structures, pipes, and tanks

I’ve seen procurement managers hesitate on the ZX1 because it seems “too basic.” But here’s the thing – if 80% of your measurements are on steel (and let’s be honest, in oil and gas facilities, that’s probably accurate), why pay for features you won’t use? The Dakota ZX Series Corrosion Gauge ZX1 model is incredibly cost-effective for routine monitoring.

Dakota ZX3: The Versatile Workhorse

Now we’re getting into serious territory. The Dakota ZX3 is where Dakota really shows what they can do. This authorized dealer in Oman favorite expands your measurement range significantly and adds programmable velocity settings.

Measurement range: 0.63 to 914.4mm (0.025 to 36 inches)

Key addition: High-speed scan mode

Best for: Multi-material facilities where you’re measuring everything from aluminum heat exchangers to thick pressure vessels

The scan mode is criminally underrated. Instead of taking individual point measurements, you can sweep the transducer across a surface and the gauge captures the minimum reading. This is absolutely clutch when you’re looking for pitting corrosion – those sneaky thin spots that can turn into major problems.

Dakota ZX5-DL: The Data Logger’s Dream

The Dakota ZX5-DL is where things get interesting for those of you who need to maintain serious documentation. That “-DL” stands for data logging, and it’s a feature that changes everything for compliance and trending analysis.

Storage capacity: 10,000 readings (40 files of 250 readings each)

Includes: PC software and data transfer cable

Why it matters: Automated reporting, trend analysis, and ironclad documentation for audits

I can’t tell you how many times I’ve heard engineers say, “I wish I had tracked that data from last year’s inspection.” With the ZX5-DL from your Dakota ZX Series Corrosion Gauge authorized dealer in Oman, you’re building a permanent record of your asset’s condition. When the auditor asks for proof of monitoring, you’re not scrambling through notebooks – you’re pulling up digital records with timestamps.

Dakota ZX6-DL: The Through-Paint Champion

Here’s where Dakota separates itself from the competition. The Dakota ZX6-DL includes Echo-Echo (EE) mode, which is basically magic for anyone dealing with coated surfaces.

Standard mode (PE): 0.63 to 914.4mm

Through-paint mode (EE): 2.54 to 152.4mm

Game-changer feature: Measures substrate thickness while ignoring coatings up to 20mm thick

Let me paint you a picture. You’ve got a tank with expensive epoxy coating. Traditional gauges force you to either grind off the coating (expensive, time-consuming, exposes the metal to corrosion) or try to subtract the coating thickness mathematically (inaccurate, unreliable). The ZX6-DL’s Dakota ZX Series Corrosion Gauge through-paint capability means you just measure through the coating. Done. Accurate. No damage.

For Corrosion Under Insulation (CUI) monitoring in refineries and petrochemical plants – which, let’s face it, is a massive concern in Oman’s industrial sector – this feature alone justifies the investment.

Why Seven Star LLC as Your Authorized Dealer in Oman for Dakota ZX Series Corrosion Gauge Changes Everything

Look, you can probably find Dakota gauges from various sources. But there’s a massive difference between buying from a random online supplier and working with Seven Star LLC as the authorized dealer in Oman for Dakota ZX Series Corrosion Gauge equipment.

When you source your Dakota ZX Series Corrosion Gauge through an authorized dealer in Oman like Seven Star LLC, you’re getting comprehensive support that extends far beyond the initial purchase. The Dakota ZX Series Corrosion Gauge performs best when backed by proper training, calibration services, and technical expertise – all of which we provide as your authorized dealer in Oman.

What “Authorized” Actually Means for Your Dakota ZX Series Corrosion Gauge Investment

Genuine Products: Every Dakota ZX Series Corrosion Gauge comes with a certificate of calibration directly from Dakota. No counterfeits, no grey market imports that might not meet specifications.

Manufacturer Warranty: Dakota offers a 5-year warranty on the Dakota ZX Series Corrosion Gauge – one of the best in the industry. But that warranty is only valid through authorized channels. Buy from anyone else, and you’re rolling the dice.

Technical Support: When you hit a snag with your Dakota ZX Series Corrosion Gauge (and everyone does eventually), you’re calling a local team in Oman who actually knows the product. Not a call center reading from a script.

Calibration Services: We provide ongoing calibration services for your Dakota ZX Series Corrosion Gauge to keep your gauges accurate and compliant with your quality management system requirements.

Our Certification Advantage for Dakota ZX Series Corrosion Gauge Support

Seven Star LLC isn’t some fly-by-night operation. We’re certified under ISO 9001, ISO 14001, ISO 45001, and ISO/TS 29001. What does that alphabet soup mean for your Dakota ZX Series Corrosion Gauge procurement? It means we have documented quality systems, environmental management, occupational health and safety practices, and petroleum industry-specific quality management.

When you’re specifying a Dakota ZX Series Corrosion Gauge from an authorized dealer in Oman, you want to know that dealer meets the same quality standards you’re held to. We do. Every Dakota ZX Series Corrosion Gauge we supply comes with full documentation and traceability.

What Makes Dakota ZX Series Corrosion Gauge Different from Every Other Thickness Gauge?

You’re probably thinking, “Okay, but don’t other manufacturers make thickness gauges?” Absolutely. But here’s why the Dakota ZX Series Corrosion Gauge keeps winning contracts in the Middle East and why procurement specialists consistently choose the Dakota ZX Series Corrosion Gauge over alternatives:

Built for Brutal Environments

Dakota engineers these gauges with an extruded aluminum body specifically designed to withstand harsh industrial conditions. We’re talking about:

- Operating temperature range: -30°C to 75°C (-22°F to 167°F)

- Weather-resistant construction: Stands up to dust, moisture, and the occasional dropped-from-a-height moment

- LCD display with backlight: Actually readable in direct Oman sunlight (you’d be surprised how many gauges fail this basic test)

The Transducer Ecosystem

Here’s something most suppliers won’t tell you: the gauge is only half the story. The transducer – that probe you actually touch to the material – makes or breaks your measurements. Dakota offers an extensive range of transducers and accessories, and as the authorized dealer in Oman, we stock the ones that matter for your applications:

- High-temperature probes: For those 500°C surfaces in fired heaters

- Small-diameter probes: Getting into tight spots on piping

- Delay line probes: For thin materials where standard probes struggle

- Long-range probes: Thick vessels and structures

Automatic V-Path Correction

This is one of those features that sounds boring but saves your bacon in real-world use. When sound travels through metal at an angle (which happens more often than you’d think), you can get false readings. Dakota’s automatic V-path correction compensates for this, giving you the true minimum thickness without requiring you to be perfectly perpendicular.

Real-World Applications for Dakota ZX Series Corrosion Gauge in Oman’s Industrial Sector

Let me get specific about where the Dakota ZX Series Corrosion Gauge from your authorized dealer in Oman absolutely shines. The Dakota ZX Series Corrosion Gauge has proven itself across every major industrial application in the region:

Oil & Gas Facilities Using Dakota ZX Series Corrosion Gauge

Pipeline inspection: The scan mode on Dakota ZX Series Corrosion Gauge ZX3 and above lets you quickly survey kilometers of pipeline, flagging areas that need closer attention.

Storage tank floors: The extended range on Dakota ZX Series Corrosion Gauge ZX3/5/6 models handles those thick tank bottoms while still resolving the thin spots that matter.

Pressure vessels: Through-paint capability on the Dakota ZX Series Corrosion Gauge ZX6-DL means you can monitor vessels without disrupting operations for coating removal.

Petrochemical Plants Deploying Dakota ZX Series Corrosion Gauge

Heat exchangers: Different materials require different velocity settings – the Dakota ZX Series Corrosion Gauge programmable velocities handle aluminum, stainless steel, exotic alloys, and everything in between.

Process piping: High-temperature capability of the Dakota ZX Series Corrosion Gauge lets you measure on warm lines without waiting for shutdown and cooldown.

Reactor walls: The Dakota ZX Series Corrosion Gauge data logging capability creates permanent records for regulatory compliance and insurance purposes.

Power Generation Facilities Trust Dakota ZX Series Corrosion Gauge

Boiler tubes: Precision measurements with the Dakota ZX Series Corrosion Gauge catch erosion-corrosion before it causes forced outages.

Cooling water systems: The Dakota ZX Series Corrosion Gauge scan mode quickly identifies areas of accelerated corrosion.

Steam lines: High-temperature probes compatible with Dakota ZX Series Corrosion Gauge maintain accuracy on operating equipment.

Marine and Offshore Applications for Dakota ZX Series Corrosion Gauge

Ship hull surveys: The Dakota ZX Series Corrosion Gauge portable, rugged construction handles the marine environment.

Platform legs: Extended range on the Dakota ZX Series Corrosion Gauge measures through marine growth (with proper surface preparation).

Subsea structures: While not fully submersible, the Dakota ZX Series Corrosion Gauge weather resistance handles the harsh offshore environment during topside inspections.

The Technical Specifications That Make Dakota ZX Series Corrosion Gauge Superior

Let’s talk specifications without putting you to sleep. The Dakota ZX Series Corrosion Gauge uses dual-element transducer technology. Why does this matter for your Dakota ZX Series Corrosion Gauge measurements?

Understanding Dual-Element Technology in Dakota ZX Series Corrosion Gauge

Single-element transducers send and receive the ultrasonic pulse through the same crystal. This creates a “dead zone” near the surface where you can’t get accurate readings. The Dakota ZX Series Corrosion Gauge uses dual-element transducers with separate send and receive crystals, eliminating this dead zone.

Practical impact for your Dakota ZX Series Corrosion Gauge: You can measure thinner materials more accurately and get reliable readings on corroded surfaces where the near-surface material properties have changed.

Frequency Range Flexibility in Dakota ZX Series Corrosion Gauge (1-10 MHz)

Different frequencies work better for different materials and conditions when using your Dakota ZX Series Corrosion Gauge:

Low frequencies (1-2.25 MHz) with Dakota ZX Series Corrosion Gauge:

- Better penetration through coarse-grained materials

- More forgiving of rough surface conditions

- Ideal for thick sections (pressure vessels, structural steel)

High frequencies (5-10 MHz) with Dakota ZX Series Corrosion Gauge:

- Better resolution for thin materials

- More precise measurements

- Best for small-diameter tubing, sheet metal, thin-wall piping

As the authorized dealer in Oman for the Dakota ZX Series Corrosion Gauge, we help you select the right frequency transducers for your specific applications. This isn’t one-size-fits-all with the Dakota ZX Series Corrosion Gauge.

Velocity Calibration Range (305 to 18,542 m/s) in Dakota ZX Series Corrosion Gauge

Sound travels at different speeds through different materials. The Dakota ZX Series Corrosion Gauge wide velocity range covers:

| Material | Approximate Velocity | Dakota ZX Series Corrosion Gauge Compatible |

|---|---|---|

| Aluminum | 6,320 m/s | ✓ |

| Steel | 5,900 m/s | ✓ (pre-calibrated) |

| Stainless Steel | 5,790 m/s | ✓ |

| Copper | 4,700 m/s | ✓ |

| Brass | 4,430 m/s | ✓ |

| Cast Iron | 4,600 m/s | ✓ |

| Glass | 5,640 m/s | ✓ |

| Plastics | 2,000-3,000 m/s | ✓ |

This flexibility means one Dakota ZX Series Corrosion Gauge handles your entire facility’s material inventory.

How Dakota ZX Series Corrosion Gauge Stacks Up: The Honest Comparison

I’m not going to bash competitors – that’s tacky and unhelpful. But I will give you the honest comparison because you deserve to know what you’re choosing with the Dakota ZX Series Corrosion Gauge.

Dakota ZX Series Corrosion Gauge vs. Generic Import Gauges

Build quality: Dakota ZX Series Corrosion Gauge aluminum body vs. plastic housings that crack in heat

Calibration: Dakota ZX Series Corrosion Gauge factory calibration with certificate vs. questionable accuracy

Support: Local authorized dealer in Oman for Dakota ZX Series Corrosion Gauge vs. “contact the factory in [country]”

Warranty: Dakota ZX Series Corrosion Gauge 5 years vs. 1 year (if any)

Transducer options: Dakota ZX Series Corrosion Gauge extensive ecosystem vs. limited or no accessories

Price difference: Maybe 20-30% more upfront

Value difference: Dakota ZX Series Corrosion Gauge massive value over the life of the equipment

Dakota ZX Series Corrosion Gauge vs. Premium European Brands

Functionality: Dakota ZX Series Corrosion Gauge comparable feature sets

Accuracy: Dakota ZX Series Corrosion Gauge same 0.01mm resolution

Durability: Dakota ZX Series Corrosion Gauge similar rugged construction

Support in Oman: Seven Star LLC as authorized dealer in Oman for Dakota ZX Series Corrosion Gauge vs. limited regional presence

Price difference: Dakota ZX Series Corrosion Gauge typically 30-40% less expensive

Value proposition: More gauge for less money with the Dakota ZX Series Corrosion Gauge, with better local support

The Dakota ZX Series Corrosion Gauge occupies the sweet spot: professional-grade performance without the premium-brand price tag.

Setting Up Your Dakota ZX: It’s Easier Than You Think

One of the biggest advantages of the Dakota ZX Series Corrosion Gauge from your authorized dealer in Oman is how quickly you can get up and running. Let me walk you through it.

Out-of-the-Box Setup (ZX1)

- Install batteries (2 AA batteries – seriously, that’s it)

- Turn on the gauge

- Apply couplant to the surface

- Press the transducer to the material

- Read the thickness

For steel measurements, you’re literally done. The ZX1 comes pre-calibrated for steel at 5,900 m/s.

Velocity Calibration (ZX3/5/6)

When measuring materials other than steel:

- Measure a test piece of known thickness

- Enter the actual thickness

- Gauge calculates and stores the correct velocity

- All subsequent measurements use this velocity

This takes about 30 seconds once you know what you’re doing.

Probe Zeroing

All Dakota ZX models use manual probe zeroing via an integrated probe disk. This compensates for the transducer’s delay and ensures accuracy:

- Place transducer on the calibration disk

- Press the zero button

- Done

You should re-zero whenever you change transducers or if you notice readings drifting.

Data Logging and Reporting (ZX5-DL and ZX6-DL Models)

If you’re investing in the data logging models of the Dakota ZX Series Corrosion Gauge from your authorized dealer in Oman, you’re getting powerful documentation capabilities. Let me show you what’s possible.

Storage Structure

40 files × 250 readings per file = 10,000 total readings

You can organize files by:

- Location (Tank 101, Tank 102, etc.)

- System (Crude unit, Reformer, Utilities)

- Date (January 2025 inspection, February 2025 inspection)

- Inspector (Team A, Team B)

Data Transfer and Software

The DL models include:

- USB data transfer cable

- PC software for download from Dakota NDT page

- Export to Excel for custom analysis

The software lets you:

- Review all stored readings

- Generate inspection reports

- Create trend graphs showing thickness loss over time

- Identify high-risk areas requiring more frequent monitoring

Building a Corrosion Monitoring Program

Here’s a practical approach using your Dakota ZX Series Corrosion Gauge:

Step 1: Baseline Survey

Document initial thickness at critical locations. Store in File 1.

Step 2: Regular Monitoring

Return to same locations on defined intervals (monthly, quarterly, annually). Store each inspection in dated files.

Step 3: Trend Analysis

Export data to Excel. Calculate corrosion rates. Project remaining life.

Step 4: Risk-Based Inspection

Focus resources on high-corrosion-rate areas identified through trending.

Step 5: Documentation

Generate reports for management, regulators, and insurance carriers.

This systematic approach transforms raw thickness measurements into actionable asset management intelligence.

Common Questions About Dakota ZX That You’re Probably Wondering

Let me address the questions that come up repeatedly when procurement specialists and engineers evaluate the Dakota ZX Series Corrosion Gauge from our authorized dealer in Oman facility.

“Can it really measure through coatings accurately?”

The ZX6-DL’s Echo-Echo mode can measure through coatings up to 20mm thick (mostly applicable to epoxy-based coatings). The technology works by ignoring the first echo (coating interface) and using multiple internal echoes from the substrate.

Important limitation: The coating must be well-bonded to the substrate. If there’s delamination or air gaps, EE mode won’t work properly. In those cases, you’re back to standard PE mode or removing the coating.

“What kind of surface preparation do I need?”

Minimum requirements:

- Remove loose rust, scale, or paint

- Clean off oil, grease, or dirt

- Surface doesn’t need to be mirror-smooth, but should be reasonably flat

Couplant application:

- Thin layer covers surface irregularities

- Creates acoustic coupling between transducer and material

- Dakota supplies couplant with each gauge

Practical tip: Rougher surfaces may require lower frequency transducers (1-2.25 MHz) for reliable coupling.

“How do I know if my gauge needs recalibration?”

Your Dakota ZX Series Corrosion Gauge from Seven Star LLC as your authorized dealer in Oman comes with a certificate of calibration. For ongoing compliance:

Recalibration intervals:

Industry standard is typically annually, but check your quality system requirements.

Signs you need recalibration:

- Readings on test blocks don’t match known values

- Inconsistent measurements on the same location

- Gauge has been dropped or physically damaged

- Operating outside specified temperature range

Our calibration service:

As the authorized dealer in Oman, Seven Star LLC provides calibration services traceable to national standards, with new certificates issued after each calibration.

“Can I use this in hazardous areas?”

Standard Dakota ZX gauges are not intrinsically safe for use in explosive atmospheres (Zone 0, 1, 2 or Division 1, 2 classified areas).

Safe usage:

- Use during non-operational periods when hazardous atmosphere is not present

- Use outside classified areas

- Obtain hot work permit if required by facility procedures

If you need measurements in live hazardous areas, contact us about intrinsically safe options or alternative methods.

“What’s the battery life like?”

Alkaline batteries: Approximately 45 hours of continuous use

NiCad rechargeable batteries: Approximately 23 hours of continuous use

Practical translation: With normal intermittent use (not continuous), a set of batteries typically lasts several weeks. Always carry spares during extended inspections.

“How accurate is it really?”

The Dakota ZX Series Corrosion Gauge provides 0.01mm (0.001″) resolution across all models. But resolution and accuracy aren’t the same thing.

Accuracy factors:

- Material uniformity and grain structure

- Surface condition and coupling

- Temperature effects on sound velocity

- Transducer selection and condition

- Proper calibration

Typical accuracy: ±0.1mm or ±1% of reading (whichever is greater) under controlled conditions with proper technique.

This is more than adequate for corrosion monitoring where you’re tracking trends and identifying problem areas, not performing precision machining.

The Complete Dakota NDT Ecosystem at Seven Star LLC

Here’s something important: the Dakota ZX Series Corrosion Gauge is just one part of a complete Non-Destructive Testing (NDT) solution portfolio we offer as the authorized dealer in Oman.

Complementary NDT Equipment

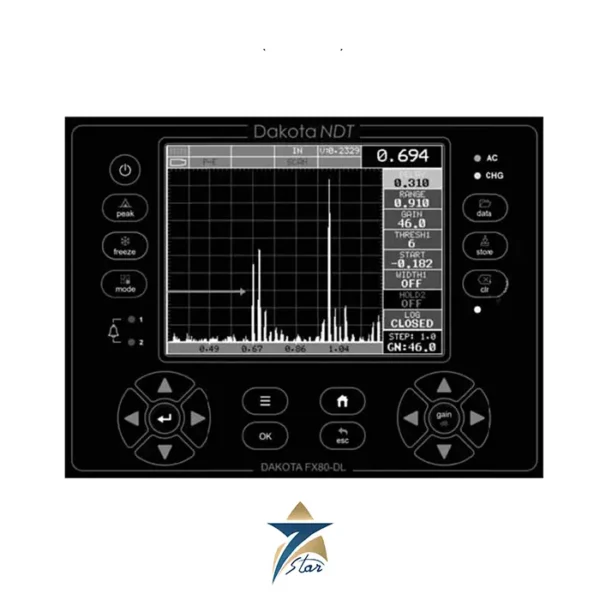

Flaw Detectors:

When you need to not just measure thickness but also detect internal defects, cracks, and discontinuities. Dakota’s flaw detection equipment uses similar ultrasonic principles but displays the full waveform for detailed analysis.

Bolt Tension Monitors:

Critical for flange integrity, pressure vessel closures, and structural connections. Uses ultrasonic measurement to determine actual bolt load vs. relying on torque values.

Thickness Gauges (Complete Range):

Beyond the ZX series, Dakota offers precision gauges for specialized applications – high-temperature measurement, through-coat measurement on non-epoxy coatings, underwater measurement, and more.

Building Your NDT Program

Smart procurement isn’t about buying individual pieces of equipment – it’s about building capability. Here’s how organizations typically grow their NDT capabilities with Seven Star LLC as their partner:

Phase 1: Basic Corrosion Monitoring

Start with Dakota ZX1 or ZX3 for routine steel measurements. Low investment, immediate value.

Phase 2: Comprehensive Documentation

Upgrade to ZX5-DL or ZX6-DL for data logging. Begin systematic trending.

Phase 3: Advanced Applications

Add through-coat capability (ZX6-DL), specialized transducers for challenging applications.

Phase 4: Full NDT Integration

Incorporate flaw detection, bolt monitoring, and other NDT technologies as needs emerge.

As your authorized dealer in Oman for the Dakota ZX Series Corrosion Gauge and complete NDT equipment line, we support this evolution with technical training, ongoing support, and equipment availability.

Investment Considerations: TCO vs. Purchase Price

Let’s talk money. The Dakota ZX Series Corrosion Gauge isn’t the cheapest option on the market. But it’s absolutely the best value, and here’s why.

Total Cost of Ownership Analysis

Initial Purchase (Example: ZX5-DL)

Let’s say $3,000 USD (actual pricing requires an RFQ – request a quote here)

Warranty Period: 5 years (vs. 1 year typical for competitors)

Annual Operating Costs:

- Batteries: ~$20

- Couplant: ~$50

- Annual calibration: ~$200

- Total: ~$270/year

5-Year TCO: $3,000 + (5 × $270) = $4,350

Compare to a $2,000 import gauge:

- Warranty: 1 year

- Typical failure after 2-3 years: $2,000 replacement cost

- Less accurate readings: potential for missed corrosion = incalculable risk

- Limited transducer options: may need additional gauges for different applications

- Poor support: wasted technician time troubleshooting = easily $500+/year

5-Year TCO: $2,000 + $2,000 (replacement) + $2,500 (troubleshooting time) = $6,500+

Dakota advantage: Lower TCO despite higher initial cost, plus significantly better performance and risk management.

Value Delivered Beyond the Numbers

Avoided unplanned shutdowns:

Catching corrosion before failure prevents emergency shutdowns costing $50,000-$500,000+ per day in lost production.

Optimized inspection intervals:

Data logging and trending allow evidence-based decisions on inspection frequency, potentially reducing inspection costs while improving safety.

Regulatory compliance:

Documented, calibrated measurements protect against regulatory violations and associated fines.

Insurance implications:

Systematic monitoring programs may reduce insurance premiums or prevent coverage disputes after failures.

When you evaluate the Dakota ZX Series Corrosion Gauge from your authorized dealer in Oman, you’re not buying a gauge – you’re investing in operational reliability and risk management.

How to Order Your Dakota ZX from Seven Star LLC

Ready to move forward? Here’s exactly how to work with us as your authorized dealer in Oman for the Dakota ZX Series Corrosion Gauge.

Step 1: Determine Your Requirements

Consider:

- Primary materials: Steel only (ZX1), or multiple materials (ZX3/5/6)?

- Coating thickness: Need through-coat capability (ZX6-DL)?

- Documentation needs: Require data logging (ZX5-DL or ZX6-DL)?

- Transducers: Standard contact measurements, or specialized applications?

Not sure? Contact our team – we help you select the right configuration.

Step 2: Submit Your RFQ

Use our Request for Quotation form to submit your requirements. Include:

- Specific model(s) of interest

- Quantity required

- Any special transducers or accessories

- Delivery timeline

- Your facility location in Oman

Step 3: Review Technical Proposal

We’ll provide:

- Detailed quotation with all components

- Technical specifications

- Delivery schedule

- Training options

- Calibration service information

- Warranty details

Step 4: Purchase and Delivery

Payment terms: Standard commercial terms available

Delivery: Stock items ship within days; special configurations within 2-4 weeks

Documentation: Certificate of calibration, user manual, warranty registration

Step 5: Training and Support

We offer:

- On-site training: Our technicians come to your facility

- Remote support: Phone and email technical assistance

- Periodic calibration: Schedule regular calibration services

- Transducer supply: Ongoing availability of consumables and accessories

Related NDT Equipment Categories

| Category | Description | Typical Applications | Browse Category |

|---|---|---|---|

| Thickness Gauges (Complete Range) | Full line of ultrasonic thickness measurement devices including specialty gauges | Corrosion monitoring, quality control, asset integrity management | Shop Thickness Gauges |

| Flaw Detectors | Ultrasonic flaw detection equipment for internal defect detection | Weld inspection, crack detection, structural integrity assessment | Shop Flaw Detectors |

| Bolt Tension Monitors | Ultrasonic bolt load measurement systems | Flange integrity, pressure vessel closures, critical fastener monitoring | Shop Bolt Tension |

| Transducers & Accessories | Wide range of probes, couplants, calibration blocks, cables | Supporting all ultrasonic measurement applications | Shop Transducers |

| Complete NDT Solutions | Browse all Non-Destructive Testing equipment and accessories | Comprehensive inspection programs across all industries | Shop All NDT |

Additional Industrial Products

| Product/Brand | Description | Product Link |

|---|---|---|

| Emerson 475 Field Communicator | HART communicator for field device configuration and diagnostics | View Product |

| Complete Dakota NDT Product Line | Comprehensive information on all Dakota Ultrasonics products available in Oman | Visit Dakota NDT Page |

Important Documents & Resources

| Document/Resource | Purpose | Link |

|---|---|---|

| Letter of Authorization | Official authorization from Dakota NDT confirming Seven Star LLC as authorized dealer | Download PDF |

| RFQ Request Form | Submit your requirements for quotation and technical proposal | Submit RFQ |

| Seven Star Main Website | Complete product catalog and company information | Visit Website |

Why Seven Star LLC Is Different

I could end this article with the typical “contact us today” spiel, but let me tell you what actually makes us different as your authorized dealer in Oman for the Dakota ZX Series Corrosion Gauge.

Local Presence, Global Standards

We’re not an international supplier trying to serve Oman from a warehouse in another country. We’re here, in Oman, with:

- Local inventory: Stock of gauges and common transducers

- In-country support: Technical team you can actually meet

- Rapid response: Same-day response to inquiries, not “we’ll get back to you”

Technical Expertise

Our team doesn’t just sell equipment – we understand the applications. We’ve worked in:

- Oil & gas production and processing

- Petrochemical manufacturing

- Power generation

- Marine and offshore

We speak your language because we’ve been in your industry.

Certified Quality Systems

Our ISO 9001, ISO 14001, ISO 45001, and ISO/TS 29001 certifications aren’t just wall decorations. They mean:

- Documented processes: Consistent service delivery

- Quality assurance: Products meet specifications

- Continuous improvement: We’re always getting better

- Supply chain integrity: Genuine products from authorized sources

Digital Infrastructure

Here’s something unique: 90% of our demand comes from our digital presence. We’re not relying on personal relationships and golf games to stay in business – we’re earning business through valuable content, technical expertise, and service quality.

This means:

- Comprehensive technical information available 24/7 on our website

- Educational content helping you make informed decisions

- Transparent pricing and specifications

- Easy online RFQ process

The Seven Star B2B Marketplace

Beyond individual equipment sales, we’re building something bigger: the Seven Star B2B Industrial Parts Marketplace. This email-based platform connects buyers with verified suppliers across the Middle East.

For you as a buyer:

- Access to wide supplier network

- Competitive quotations automatically delivered

- No registration fees or hidden costs

- Streamlined procurement process

For your organization:

- One trusted partner for diverse industrial requirements

- Reduced sourcing time and effort

- Competitive pricing through supplier network

- Quality assurance through Seven Star oversight

The Bottom Line on Dakota ZX Series

Look, corrosion monitoring isn’t glamorous. Nobody’s getting excited about ultrasonic thickness gauges at industry conferences (okay, maybe NDT specialists do, but they’re a special breed). But here’s the truth: effective corrosion management is the difference between:

Scenario A:

Systematic monitoring → detected thinning → planned repair during scheduled shutdown → $50,000 cost → no production loss

Scenario B:

Infrequent inspections → undetected corrosion → catastrophic failure → emergency shutdown → $500,000+ cost → safety incident → regulatory scrutiny → reputation damage

The Dakota ZX Series Corrosion Gauge from Seven Star LLC as your authorized dealer in Oman is your defense against Scenario B.

What You’re Really Buying

Accuracy: 0.01mm resolution, properly calibrated, with manufacturer backing

Reliability: 5-year warranty, rugged construction, proven in Middle East conditions

Capability: Entry-level to advanced, covering your complete thickness measurement needs

Support: Local authorized dealer with technical expertise and parts availability

Value: Professional-grade performance at mid-range pricing with best-in-class warranty

Making the Decision

If you’re still on the fence, ask yourself these questions:

- What’s the cost of an unplanned shutdown at my facility?

- Do I have confidence in my current corrosion monitoring program?

- Am I documenting thickness measurements for trending analysis?

- Can I measure through coatings without removing them?

- Do I have local support for my current thickness gauges?

If any of those questions made you uncomfortable, it’s time to upgrade to the Dakota ZX Series Corrosion Gauge.

Your Next Steps

Today:

- Review the Dakota ZX product pages on our website

- Download the Letter of Authorization confirming our authorized dealer status

- Identify which model(s) fit your applications

This Week:

- Submit an RFQ through our website

- Discuss your specific requirements with our technical

Dakota NDT Official Website

Visit the official Dakota NDT website to explore full product documentation, detailed datasheets, software updates, and official manufacturer resources for professional applications.

Letter of Authorisation

Official authorization letter confirming Seven Star LLC as an approved partner of Dakota NDT, covering sales and technical support activities in Oman.

Technical Consultation & Inquiry

Our technical team assists with product selection, specifications, applications, and quotations for Dakota NDT instruments.