Bently Nevada 991-06-50-01-01 Thrust Transmitter – Shaft Thrust Position Monitoring

Overview

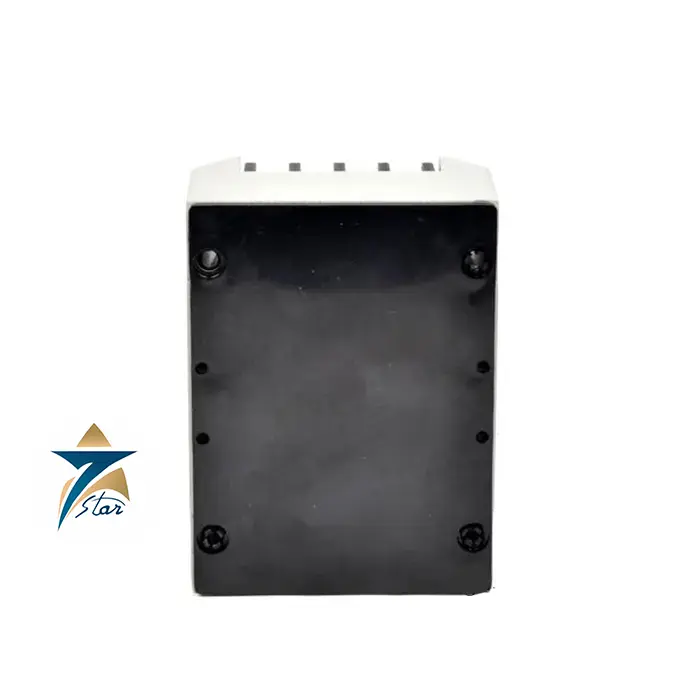

Bently Nevada 991-06-50-01-01 Thrust Transmitter

The Bently Nevada 991-06-50-01-01 is part of the trusted 991 Thrust Transmitter series, engineered specifically for continuous monitoring of axial shaft position (thrust) in critical rotating equipment. Thrust position measurement is essential in applications where excessive axial movement can lead to bearing damage, seal failure, or catastrophic machine breakdown.

This thrust transmitter accepts input from Bently Nevada proximity probes and conditions the displacement signal into a stable and proportional 4–20 mA analog output, making it suitable for direct connection to plant control systems and protection logic.

Download Datasheet

Thrust Position Monitoring for Rotating Machinery

In turbines, compressors, pumps, and large electric motors, axial movement must remain within strict limits. The Bently Nevada 991-06-50-01-01 Thrust Transmitter provides continuous real-time feedback on shaft thrust position, allowing operators and maintenance teams to:

-

Detect abnormal axial movement early

-

Prevent thrust bearing damage

-

Reduce unplanned shutdowns

-

Support predictive and condition-based maintenance strategies

The transmitter plays a critical role in safeguarding high-value rotating assets where thrust control is essential for long-term reliability.

Industrial-Grade Design

The 991-06-50-01-01 features a compact and rugged industrial design suitable for harsh operating environments. It is built to withstand:

-

Electrical noise and interference

-

Mechanical vibration

-

Temperature variations

-

Continuous operation in industrial plants

Its loop-powered architecture simplifies wiring and reduces installation complexity, especially in retrofit applications.

Key Technical Features

-

Model / Part Number: 991-06-50-01-01

-

Product Type: Thrust (Axial Position) Transmitter

-

Measurement Principle: Shaft thrust position via proximity probes

-

Output Signal: 4–20 mA proportional to thrust position

-

Power Supply: Loop-powered (2-wire)

-

Probe Compatibility: Bently Nevada proximity probes

-

Mounting: Panel or DIN-rail mounting (depending on configuration)

-

Application Type: Continuous online thrust monitoring

Integration with Control & Protection Systems

The 4–20 mA output from the Bently Nevada 991-06-50-01-01 allows seamless integration with:

-

PLC systems

-

DCS platforms

-

SCADA monitoring systems

-

Machinery protection and alarm logic

This makes the transmitter suitable both for monitoring and protective shutdown strategies in critical machinery trains.

Typical Applications

The Bently Nevada 991-06-50-01-01 Thrust Transmitter is commonly used in:

-

Steam and gas turbines

-

Centrifugal and axial compressors

-

Large industrial pumps

-

Electric motors with thrust bearings

-

Power generation plants

-

Oil & gas and petrochemical facilities

In these applications, accurate thrust position monitoring is essential to maintain safe operating conditions.

FAQ

What does the Bently Nevada 991-06-50-01-01 measure?

It measures shaft thrust (axial position) and converts it into a proportional 4–20 mA signal.

Why is thrust monitoring important?

Excessive axial movement can damage thrust bearings and lead to severe machine failure. Continuous monitoring helps prevent this.

Can this transmitter connect directly to a PLC?

Yes. The 4–20 mA output is fully compatible with PLC, DCS, and SCADA systems.

Is this transmitter suitable for harsh industrial environments?

Yes. It is designed for continuous operation in demanding industrial conditions.

Call to Action

For genuine Bently Nevada 991-06-50-01-01 Thrust Transmitter and expert support for thrust monitoring applications, contact Seven Star LLC for pricing, availability, and technical consultation.

Bently Nevada, a division of Baker Hughes, is a global leader in asset condition monitoring and protection technologies. For over six decades, the company has set the industry standard in machinery diagnostics, vibration analysis, and predictive maintenance solutions.

Its advanced systems and sensors are designed to ensure maximum equipment uptime, safety, and efficiency across power generation, oil & gas, and industrial manufacturing sectors. From vibration probes and monitoring racks to software platforms like System 1, Bently Nevada products enable real-time insight and data-driven decision-making.

Seven Star LLC supplies genuine Bently Nevada equipment, sensors, and monitoring solutions to clients across the Middle East, providing trusted reliability, expert support, and seamless integration for modern industrial operations.

Reviews

There are no reviews yet.