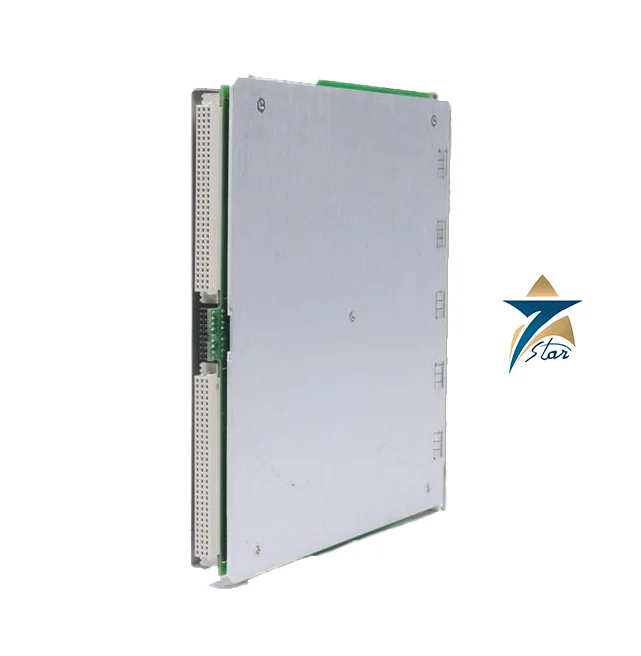

3500/40M Proximitor® Monitor

Overview

The Bently Nevada 3500/40M Proximitor® Monitor is the standard eddy-current proximity-probe monitor for the 3500 machinery protection system. It continuously conditions proximity transducer signals, derives vibration/position parameters in engineering units, compares them against programmable Alert/Danger setpoints, and publishes high-resolution data to the rack interface for diagnostics—delivering protection and condition-monitoring in one module. The 40M is a four-channel monitor; each channel is independently configurable and integrates cleanly with the 3500 Rack Configuration Software and System 1 environment via the rack interface.

What it Measures (per-channel functions)

Each channel can be assigned one of the standard proximity functions used on rotating assets, allowing the same module to cover multiple roles in a train: Radial Vibration, Thrust Position, Differential Expansion, Eccentricity, and REBAM (rolling-element bearing absolute measurement). This flexibility lets you combine two radial bearings plus a thrust channel in a single card, or deploy special mixes for steam-turbine DE/thermal growth monitoring—without changing hardware.

Protection & Alarming

The 40M continuously evaluates derived static values (overall, gap/position, etc.) and applies user-programmable Alert/Danger thresholds with time delays and latching options. Alarms are time-stamped and made available to the rack for relays and event logs, supporting both automatic trips and fast root-cause analysis.

Data for Diagnostics (System 1)

In addition to protection, the 40M provides the dynamic signal path that enables waveforms, orbits, and trends in System 1 when the rack is equipped with a Transient Data Interface (3500/22M TDI). This pairing preserves protection independence in the monitors while streaming static/dynamic/transient data over Ethernet for condition-based maintenance.

Integration & Operation

-

4-channel card, hot-swappable in the 3500 rack; front LEDs report OK/fault status.

-

Accepts Bently Nevada proximity transducers (eddy-current) and scales them to engineering units.

-

Configured with 3500 Rack Configuration Software; data collection and remote work through System 1 via the TDI.

-

Part of a modular system designed to meet API 670 requirements for machinery protection.

Typical Applications

Compressor radial vibration and thrust position; steam/gas turbine radial/DE/thermal growth; large motors/generators shaft vibration; critical pumps and fans requiring API-class protection with deep diagnostics.

Compatibility & Ordering Notes

Provide your probe model/cable lengths, intended channel mix (e.g., 2× radial + 1× thrust), and System 1/TDI details so we can confirm firmware compatibility and I/O. If you are upgrading from older 3500 monitors, we’ll validate slot positions and alarm philosophy to match your site standard.

What’s Included

3500/40M Proximitor® Monitor module only. Probes, I/O modules, rack hardware, and cabling are quoted separately.

Call to Action

Need the right channel set, probe lengths, or DE/thrust configuration for your machine? Send your rack BOM and rotor layout—Seven Star LLC will validate the setup, confirm availability/lead time, and offer the best regional pricing.

Bently Nevada, a division of Baker Hughes, is a global leader in asset condition monitoring and protection technologies. For over six decades, the company has set the industry standard in machinery diagnostics, vibration analysis, and predictive maintenance solutions.

Its advanced systems and sensors are designed to ensure maximum equipment uptime, safety, and efficiency across power generation, oil & gas, and industrial manufacturing sectors. From vibration probes and monitoring racks to software platforms like System 1, Bently Nevada products enable real-time insight and data-driven decision-making.

Seven Star LLC supplies genuine Bently Nevada equipment, sensors, and monitoring solutions to clients across the Middle East, providing trusted reliability, expert support, and seamless integration for modern industrial operations.

Reviews

There are no reviews yet.