Blog

Dakota NDT Authorized Supplier and Distributors in Oman

When Precision Meets Partnership: A New Chapter in Middle East NDT

Let me tell you something that’s been missing from the Omani industrial landscape—until now. Picture this: You’re standing in front of a critical pipeline at 2 AM, your thickness gauge is giving you questionable readings, and your entire maintenance schedule hangs in the balance. Sound familiar? Well, here’s the thing—Seven Star LLC, your trusted Dakota NDT Authorized Supplier in Oman, just changed the game entirely.

As the official Dakota NDT Representative in Oman, we’re not just another distributor throwing catalogues at you. We’re the bridge between world-class American engineering and the demanding realities of Middle Eastern industrial operations. And honestly? It’s about time someone got this right.

Why This Partnership Matters (And Why You Should Care)

I’ve spent enough time in the oil & gas sector to know that procurement isn’t just about buying equipment—it’s about finding partners who understand the stakes. When a refinery in Sohar needs corrosion monitoring or when a petrochemical facility in Salalah requires precision thickness measurement, you can’t afford mediocrity.

Seven Star LLC operates as the exclusive Dakota NDT Authorized Supplier across the Sultanate of Oman, and here’s why that matters: We’re not middlemen. We’re your technical partners, backed by ISO 9001, ISO 14001, ISO 45001, and ISO/TS 29001 certifications. That’s not corporate jargon—that’s your assurance that when you need support, you’re getting world-class expertise.

The Dakota Difference: Built for Your Reality

Dakota Ultrasonics didn’t become an industry leader by accident. Their ultrasonic thickness gauges are engineered for the environments you work in—the heat, the humidity, the pressure (both literal and figurative). As your Dakota NDT Representative in Oman, we’ve seen firsthand how their technology solves real problems:

ThruPaint™ Technology (EE Mode): This isn’t marketing fluff. It’s the difference between shutting down operations to remove coating layers and getting accurate substrate readings through the paint. For Corrosion Under Insulation (CUI) monitoring—a massive concern in our region—this feature alone justifies the investment.

Advanced Signal Processing: Adjustable Gain and Time Dependent Gain (TDG) ensure reliable readings even in noisy, highly attenuative materials. Because let’s face it, your facility isn’t a laboratory, and your equipment needs to work in the real world.

Integrated Data Logging: The DL models store up to 10,000 readings. That’s not just convenience—that’s compliance, documentation, and the ability to trend corrosion patterns over time.

Industry-Leading 5-Year Warranty: When Dakota stands behind their products for five years, that tells you something about build quality. As the Dakota NDT Authorized Supplier in Oman, we’re equally committed to supporting you throughout that lifecycle.

What Makes Seven Star LLC Your Ideal NDT Partner?

Here’s where I need to be direct with you. The Middle East is flooded with suppliers promising the moon. But how many of them attribute 90% of their demand to a strong digital footprint and genuine expertise? We do. How many actually understand the specific technical demands of Omani facilities? We do.

Seven Star LLC isn’t new to this game. We’ve been providing design, supply, construction, installation, and commissioning of automation and control systems across the region. Our focus? Oil & gas, petrochemicals, refineries, and power plants—the industries where precision NDT equipment isn’t optional, it’s essential.

As the official Dakota NDT Representative in Oman, we bring you:

- Local Expertise, Global Standards: We understand regional challenges (extreme temperatures, corrosive environments, demanding operational schedules) while maintaining international quality standards.

- Comprehensive Product Range: From basic thickness gauges to advanced flaw detectors, we stock the complete Dakota NDT lineup. Visit our NDT equipment section to explore the full catalog.

- Technical Support That Actually Helps: Need calibration? Installation support? Training? We’re here, in Oman, ready to assist. No waiting for international support teams to wake up.

Your Dakota NDT Equipment Arsenal: What We Offer

Let’s talk products. As your Dakota NDT Authorized Supplier, we’ve curated our inventory based on what actually works in Middle Eastern industrial environments. Here’s what you need to know:

Thickness Gauges: The Backbone of Corrosion Monitoring

The thickness gauges category is where Dakota truly shines, and it’s where most of our clients start their NDT journey.

Dakota ZX Series (ZX-2, ZX-3, ZX-5, ZX-6): These are your workhorses. Compact, reliable, and packed with features that matter. The ZX-5 and ZX-6 models include advanced A-Scan displays for those moments when you need to see exactly what’s happening beneath the surface. Perfect for pipeline inspections, tank floor surveys, and routine corrosion monitoring.

Dakota PZX Precision Series: When you need sub-millimeter accuracy—think aerospace components, precision manufacturing, or quality control applications—the PZX delivers. We’re talking resolution that lets you catch issues before they become failures.

Dakota MX Series: Multi-echo technology that ignores coatings up to 20mm thick. This is your solution for through-coat measurements, saving countless hours of surface preparation.

High-Temperature Models: Some Dakota gauges handle surfaces up to 500°C. In refineries where hot work is the norm, this capability is a game-changer.

Flaw Detectors: Beyond Thickness Measurement

While thickness gauges get most of the attention, flaw detectors are equally critical for comprehensive NDT programs.

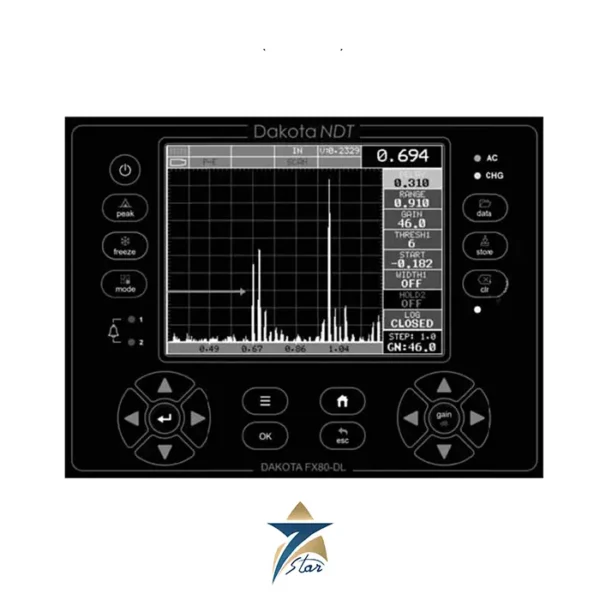

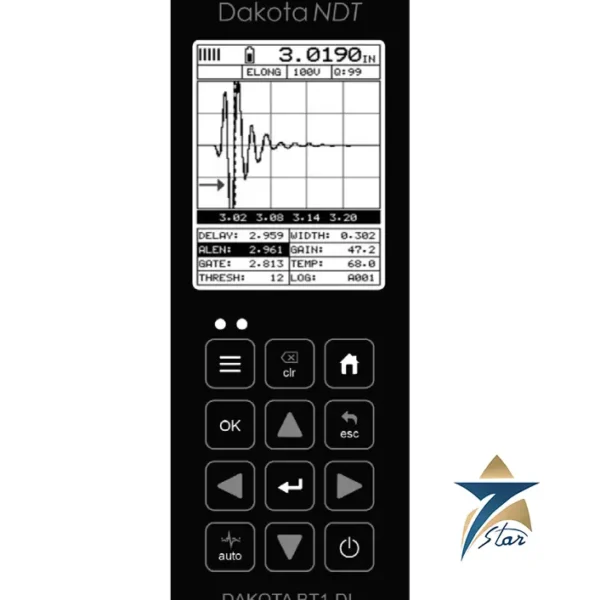

Dakota FX Series (FX3, FX70DL, FXD): Portable ultrasonic flaw detection for welds, structural inspections, and integrity assessments. The FX70DL features digital LCD displays and integrated data logging—essential for documentation and compliance in our heavily regulated industries.

High Gain Flaw Detectors: Enhanced sensitivity for detecting flaws in thick materials or challenging geometries. When standard equipment can’t penetrate, these units step up.

A-Scan Capable Models: Real-time A-Scan displays for flaw sizing and characterization. It’s the difference between knowing there’s a defect and understanding its exact nature and dimensions.

Specialized Tools: Bolt Tension Monitors and Accessories

Don’t overlook the bolt tension category. Ultrasonic bolt load measurement is increasingly critical for:

- Flange integrity monitoring

- Pressure vessel assembly verification

- Turbine maintenance

- Structural steel connections

The Dakota Bolt Tension Monitor and Bolt Elongation Meter provide precision stress monitoring, ensuring connections remain secure throughout operational lifecycles.

And let’s not forget transducers and accessories—the unsung heroes of any NDT program. Proper transducer selection dramatically impacts measurement accuracy and reliability.

Frequently Asked Questions: Your Dakota NDT Queries Answered

What ultrasonic thickness gauges does Dakota NDT offer through Seven Star LLC in the Middle East?

As the Dakota NDT Authorized Supplier in Oman, we offer the complete Dakota NDT product line. This includes the ZX Series (ZX-2, ZX-3, ZX-5, ZX-6) for general thickness measurement and corrosion monitoring, the PZX Precision Series for high-accuracy applications, the MX Series for multi-echo and through-coat measurements, specialized high-temperature gauges, and underwater IP68-rated models for subsea inspections.

Every product we stock is backed by Dakota’s engineering excellence and our local technical support. Whether you need a basic gauge for routine inspections or a sophisticated instrument for critical applications, we’ve got you covered.

How does the Seven Star LLC and Dakota NDT partnership benefit Middle East procurement?

Here’s the straight answer: Procurement teams in the Middle East face unique challenges—extended lead times, unclear technical support, calibration logistics, and questions about product authenticity. As the official Dakota NDT Representative in Oman, Seven Star LLC eliminates these pain points.

You get:

- Local inventory for faster delivery (no more waiting months for international shipments)

- Verified authenticity (download our Letter of Authorization directly)

- Regional calibration services aligned with your maintenance schedules

- Technical training conducted in your facility, in your timeframe

- Warranty support handled locally, not through international channels

Our digital-first approach means 90% of our customers find us online, research products thoroughly, and make informed decisions before reaching out. That’s procurement efficiency redefined.

Where can I source Dakota NDT thickness gauges in Oman or GCC countries?

Right here. Seven Star LLC is your authorized source for Dakota NDT equipment throughout Oman. While we’re headquartered in the Sultanate, our network extends across GCC countries, supporting major industrial projects from Kuwait to the UAE.

Visit our Dakota NDT page for product specifications, application guides, and technical resources. Need something specific? Use our RFQ Request Form and our team will respond with detailed quotations tailored to your requirements.

What industries in the Middle East use Dakota NDT ultrasonic tools most?

As your Dakota NDT Authorized Supplier, we serve these primary sectors:

Oil & Gas: Pipeline integrity, storage tank inspections, offshore platform monitoring, pressure vessel assessments. Dakota’s ThruPaint™ technology is particularly valued for CUI monitoring in this sector.

Petrochemicals: Reactor monitoring, corrosion tracking in aggressive chemical environments, precision measurement for critical components.

Refineries: High-temperature applications, catalyst bed inspections, heat exchanger monitoring, furnace tube thickness measurement.

Power Generation: Turbine component inspection, boiler tube monitoring, structural integrity assessments.

Marine & Offshore: Subsea inspections using IP68-rated underwater gauges, hull thickness surveys, offshore platform maintenance.

Manufacturing: Quality control, precision measurement, material verification across aerospace, automotive, and general manufacturing.

Are Dakota NDT products certified for oil & gas applications in the region?

Absolutely. Dakota Ultrasonics products meet or exceed international standards relevant to oil & gas operations. More importantly, Seven Star LLC operates an Integrated Management System certified under ISO 9001 (quality), ISO 14001 (environmental), ISO 45001 (occupational health & safety), and ISO/TS 29001 (petroleum, petrochemical, and natural gas industries).

When you source Dakota NDT equipment through us as your Dakota NDT Representative in Oman, you’re getting products that align with both manufacturer specifications and regional compliance requirements. Our documentation packages support ADNOC, PDO, ORPIC, and other major operators’ vendor qualification processes.

What is the lead time for Dakota NDT gauges via Seven Star LLC?

This is where being the local Dakota NDT Authorized Supplier makes a real difference. For our stocked items—which include the most popular ZX and PZX models—we’re talking days, not weeks. Standard configurations often ship within 48-72 hours.

For specialized configurations or bulk orders, lead times vary based on customization requirements and Dakota’s production schedule. However, our direct relationship with Dakota Ultrasonics means we get priority allocation and transparent communication about delivery timelines.

Check current stock status by visiting our NDT category page or submitting an inquiry through our RFQ form. We’ll give you honest timelines, not optimistic guesses.

Does Seven Star LLC provide calibration services for Dakota NDT equipment?

Yes, and this is crucial. NDT equipment is only as good as its calibration. As your Dakota NDT Representative in Oman, we provide comprehensive calibration services aligned with ASTM E797, manufacturer specifications, and your operational schedules.

Our calibration services include:

- Initial calibration before equipment deployment

- Periodic recalibration based on manufacturer recommendations or your internal protocols

- On-site calibration for facilities with multiple units or scheduling constraints

- Calibration documentation traceable to national/international standards

- Calibration block supply (standard test blocks for gauge verification)

This isn’t outsourced—it’s handled by our technical team who understand both Dakota equipment and regional operational requirements.

How accurate are Dakota NDT thickness gauges for corrosion monitoring?

Let’s get specific. Dakota’s Precision Series (PZX models) offer resolution as fine as 0.001mm (0.00004″), making them among the most accurate portable thickness gauges available. For corrosion monitoring applications, the ZX Series typically provides resolution of 0.01mm (0.0004″), which exceeds requirements for most industrial applications.

But accuracy isn’t just about specifications—it’s about real-world performance. Dakota’s signal processing technology (Adjustable Gain, TDG) ensures consistent readings even as material conditions deteriorate. The multi-echo capability eliminates coating thickness from measurements, giving you true substrate values.

As the Dakota NDT Authorized Supplier in Oman, we help clients establish baseline thickness data and trend corrosion rates over time. With the integrated data loggers storing up to 10,000 readings, you can build comprehensive corrosion management programs.

What support does Seven Star LLC offer for Dakota NDT installations?

Here’s what sets us apart as your Dakota NDT Representative in Oman: We don’t just ship equipment and disappear. Our support includes:

Pre-Installation Consultation: Understanding your application, selecting the right equipment configuration, and planning deployment logistics.

Installation Support: While handheld NDT devices don’t require complex installation, we provide on-site training and initial deployment assistance for major projects.

Operator Training: Comprehensive training on proper technique, data interpretation, and equipment maintenance. We can conduct this at your facility or ours.

Technical Troubleshooting: When issues arise (equipment, application, or interpretation questions), our local team responds quickly.

Ongoing Support: Regular check-ins, calibration reminders, and proactive maintenance recommendations.

Visit any of our specialized product categories—thickness gauges, flaw detectors, bolt tension, or transducers & accessories—and you’ll find technical resources to complement our hands-on support.

Can Seven Star LLC handle bulk orders of Dakota NDT ultrasonic devices?

Absolutely. As the official Dakota NDT Authorized Supplier for Oman, we’re equipped to handle everything from single-unit purchases to enterprise-wide deployments.

For bulk orders, we offer:

- Volume pricing that respects your budget constraints

- Phased delivery aligned with your project milestones

- Customized configurations for fleet standardization

- Comprehensive training programs for your entire NDT team

- Ongoing support contracts for large deployments

Our Seven Star B2B Marketplace is designed specifically for industrial procurement teams managing complex requirements. It’s an email-based platform that connects buyers with verified suppliers—no registration fees, no hidden costs, just efficient sourcing.

Submit your bulk order requirements through our RFQ form and our procurement specialists will develop a comprehensive proposal tailored to your timeline and specifications.

The Technical Deep Dive: Understanding Dakota’s Core Technologies

Let me get a bit technical here because, honestly, understanding what makes Dakota NDT equipment exceptional helps you make better procurement decisions.

ThruPaint™ (EE Mode): The CUI Solution

Corrosion Under Insulation is insidious. It happens where you can’t see it, accelerates in the presence of moisture, and by the time it’s detected through conventional means, significant damage has occurred. Dakota’s ThruPaint™ technology uses echo-to-echo measurement mode to ignore coating layers (paint, epoxy, even some insulation materials) and measure the actual substrate thickness.

The physics is elegant: The gauge sends an ultrasonic pulse, ignores the initial reflection from the coating surface, and instead measures the time between successive back-wall echoes from the metal substrate. This means you can conduct corrosion surveys without costly and time-consuming surface preparation.

For facilities across Oman—where insulated pipes and vessels are standard—this technology alone makes Dakota the Dakota NDT Authorized Supplier of choice.

Signal Processing: Making Sense of Noisy Environments

Industrial environments are electrically noisy, materials can be heterogeneous, and surfaces are rarely pristine. Dakota’s Adjustable Gain and Time Dependent Gain (TDG) features adapt to these realities.

Adjustable Gain lets you increase receiver sensitivity for challenging materials (cast iron, fiberglass-reinforced plastics, composites) or decrease it when working with highly reflective metals.

Time Dependent Gain automatically increases amplification for deeper echoes, compensating for signal attenuation as sound energy travels through material. This ensures that thickness measurements on thick-walled vessels are as reliable as those on thin pipework.

As your Dakota NDT Representative in Oman, we help you configure these parameters for your specific applications, turning complex technology into practical solutions.

Data Management: From Measurements to Insights

The integrated data loggers on Dakota DL models aren’t just about storing numbers—they’re about transforming raw measurements into actionable intelligence. With capacity for 10,000 readings, you can:

- Map corrosion across entire facilities, creating heat maps that prioritize maintenance activities

- Trend thickness over time, predicting remaining service life and planning replacements before failures occur

- Generate compliance reports that satisfy regulatory requirements and internal standards

- Archive historical data for forensic analysis after incidents or for continuous improvement initiatives

Our team helps clients establish data management protocols that integrate Dakota measurements into broader asset integrity programs.

Product Comparison Table: Finding Your Ideal Dakota Gauge

To make your procurement decision easier, here’s a practical comparison of Dakota’s core thickness gauge families:

| Model Series | Primary Application | Key Features | Typical Industries | Resolution | Price Point |

|---|---|---|---|---|---|

| ZX-2 | Basic thickness measurement | Single-echo, simple operation | General manufacturing, light industrial | 0.01mm | Entry-level |

| ZX-3 | Corrosion monitoring | Compact, durable, multiple materials | Pipelines, storage tanks, vessels | 0.01mm | Mid-range |

| ZX-5 | Advanced NDT | High-resolution A-Scan, extensive materials library | Oil & gas, petrochemical, aerospace | 0.01mm | Professional |

| ZX-6 | Professional inspection | Full A-Scan, advanced diagnostics, extended memory | Refineries, power generation, marine | 0.01mm | Premium |

| PZX | Precision measurement | Sub-millimeter accuracy, narrow beams | Aerospace, precision manufacturing, R&D | 0.001mm | Specialized |

| MX-3 | High-temperature | Dual-element probe, handles up to 500°C surfaces | Refineries, furnaces, heat treatment | 0.01mm | Specialized |

| Multi-Echo | Through-coat | Ignores coatings up to 20mm, ThruPaint™ | CUI monitoring, insulated systems | 0.01mm | Professional |

Every model listed here is available through Seven Star LLC, your Dakota NDT Authorized Supplier in Oman. Visit our thickness gauges section for detailed specifications and current pricing.

Beyond Gauges: Complete NDT Solutions

As your Dakota NDT Representative in Oman, we recognize that thickness gauges are just one component of comprehensive NDT programs. That’s why our partnership extends to Dakota’s full product ecosystem:

Flaw Detection Equipment

Internal flaws—cracks, voids, inclusions, laminations—can’t be detected through thickness measurement alone. Dakota’s flaw detectors provide ultrasonic flaw detection capabilities for:

- Weld inspection (assessing weld quality, detecting lack of fusion, finding crack initiation sites)

- Structural integrity (bridge components, building structures, offshore platforms)

- Forging quality control (detecting internal voids in forgings and castings)

- In-service inspection (finding fatigue cracks, stress corrosion cracking, hydrogen-induced cracking)

The FX Series offers portable, rugged instruments suitable for field deployment. With features like DAC/TCG curves, video recording, and comprehensive reporting, these tools support compliance with ASME, API, and international NDT standards.

Bolt Tension Monitoring

I’ve seen too many facilities overlook bolt integrity until a flange leak occurs. Dakota’s bolt tension monitors use ultrasonic measurement to determine bolt elongation, which correlates directly to tension (and therefore clamping force).

Applications include:

- Flange assembly verification (ensuring proper gasket compression)

- Critical fastener monitoring (turbines, pressure vessels, structural connections)

- Maintenance verification (confirming proper torque after reassembly)

- Predictive maintenance (detecting bolt relaxation before leaks occur)

This technology is particularly valuable in the oil & gas sector, where flange integrity directly impacts safety and environmental protection.

Transducers and Accessories

The right transducer makes all the difference. As the Dakota NDT Authorized Supplier in Oman, we stock a comprehensive range of transducers and accessories:

- Dual-element transducers for near-surface resolution and high-temperature applications

- Contact transducers in various frequencies (2.25MHz, 5MHz, 10MHz) for different materials and thicknesses

- Delay line transducers for thin materials or hot surfaces

- Angle beam transducers for weld inspection and flaw detection

- Couplants, calibration blocks, and carrying cases

Proper transducer selection—matching frequency, element size, and configuration to your application—significantly impacts measurement accuracy and repeatability. Our technical team provides guidance based on your specific materials, thickness ranges, and surface conditions.

Why Digital Procurement Matters: The Seven Star Advantage

Here’s something most suppliers won’t tell you: The way you find, evaluate, and purchase NDT equipment matters as much as the equipment itself. Seven Star LLC has invested heavily in digital infrastructure because we believe procurement should be transparent, efficient, and data-driven.

Our Seven Star B2B Marketplace represents a fundamental shift in industrial sourcing:

For Procurement Teams:

- Access verified suppliers without navigating dozens of websites

- Submit detailed part requests via familiar email communication

- Receive competitive quotations quickly, supported by automated matching

- Compare options transparently with all information in one place

- Make informed decisions based on specifications, pricing, and delivery timelines

For Technical Specialists:

- Research products thoroughly with comprehensive technical documentation

- Compare specifications across Dakota’s product range

- Access application guides specific to your industry and challenges

- Download certification documentation for vendor qualification processes

- Connect directly with technical support for application-specific questions

This digital-first approach is why 90% of our demand comes from online research—procurement teams value the ability to evaluate options independently before engaging with sales.

Real-World Applications: Dakota NDT in Action Across Oman

Let me share some scenarios where Dakota NDT equipment, sourced through Seven Star LLC as your Dakota NDT Authorized Supplier, solves real problems:

Scenario 1: Refinery Corrosion Monitoring Program

A major refinery in Sohar needed to implement a risk-based inspection program for their crude unit. Over 5,000 measurement points required quarterly inspection. Traditional methods (surface preparation, manual measurement, paper-based recording) consumed excessive resources.

Solution: Dakota ZX-5DL thickness gauges with ThruPaint™ technology eliminated surface prep requirements. Integrated data loggers enabled digital record-keeping, automated trending, and risk prioritization. Result: 60% reduction in inspection time, improved data quality, earlier detection of corrosion trends.

Scenario 2: Pipeline Integrity Assessment

An oil & gas operator needed to assess pipeline integrity across a remote field with limited access to calibration facilities and technical support.

Solution: Dakota ZX-3 gauges—compact, rugged, and reliable—combined with on-site training from our team. The 5-year warranty provided long-term confidence. Local calibration services from Seven Star LLC ensured ongoing accuracy without logistical nightmares.

Scenario 3: Petrochemical Precision Measurement

A petrochemical facility required sub-millimeter accuracy for quality control on specialized components with tolerances under 0.1mm.

Solution: Dakota PZX Precision Series with 0.001mm resolution. As your Dakota NDT Representative in Oman, we provided application-specific training and calibration protocols aligned with their quality management system.

Scenario 4: High-Temperature Furnace Inspections

A furnace operator needed thickness measurements on refractory-lined vessels operating at temperatures exceeding 400°C.

Solution: Dakota MX-3 high-temperature gauge with specialized transducers rated for extreme heat. Our team developed safe inspection procedures and conducted operator training specific to high-temperature applications.

These aren’t hypothetical examples—they’re real projects where Dakota NDT equipment, properly specified and supported, delivered measurable value.

Making the Purchase: Your Path Forward

Alright, let’s talk about actually getting Dakota NDT equipment into your facility. As the official Dakota NDT Authorized Supplier in Oman, we’ve streamlined the procurement process:

Step 1: Explore Your Options

Start at our Dakota NDT page for an overview of available products, applications, and technical resources. Browse specific categories:

Take your time. Review technical specifications. Download our Letter of Authorization to verify our status as your Dakota NDT Representative in Oman.

Step 2: Submit Your Requirements

Use our RFQ Request Form to detail your specific needs. The more information you provide (application, materials, thickness ranges, environmental conditions, quantity, timeline), the better we can tailor our recommendation.

Our team reviews every inquiry personally—this isn’t an automated response system. We assess your requirements against Dakota’s product capabilities and our local inventory.

Step 3: Receive Your Quotation

Within 24-48 hours (often sooner), you’ll receive a detailed quotation including:

- Product specifications matched to your application

- Pricing (transparent, competitive, volume-sensitive)

- Delivery timelines (honest, realistic, based on current inventory)

- Support options (training, calibration, warranty details)

- Documentation (certifications, user manuals, compliance records)

Step 4: Technical Consultation (Optional)

Not sure which Dakota model best fits your needs? Schedule a consultation with our technical team. As your Dakota NDT Authorized Supplier, we’re incentivized to get this right—proper equipment selection leads to customer satisfaction, repeat business, and long-term partnerships.

We can arrange product demonstrations, discuss application-specific challenges, and provide references from similar installations across the region.

Step 5: Order, Delivery, and Support

Once you approve the quotation:

- Order confirmation with detailed delivery schedule

- Shipping (carefully packaged, tracked, insured)

- Delivery verification ensuring everything arrives in perfect condition

- Initial calibration (if requested) before deployment

- Training coordination at your facility or ours

- Ongoing support throughout the equipment lifecycle

This isn’t transactional—it’s relational. We’re building long-term partnerships with procurement and maintenance teams across Oman.

The Seven Star Commitment: More Than Just Equipment Supply

Let me be completely honest with you. Anyone can import Dakota NDT equipment and call themselves a supplier. What separates Seven Star LLC as your Dakota NDT Representative in Oman is our comprehensive approach to industrial partnerships.

We’re not in the business of one-time sales. We’re building an ecosystem where industrial facilities have reliable access to world-class equipment, local technical support, and transparent procurement processes.

Our commitments to you:

Authenticity: Every Dakota product we sell comes with full manufacturer warranty and documentation. Download our Letter of Authorization anytime.

Local Presence: We’re here in Oman. When you need support, calibration, training, or troubleshooting, we respond quickly because we’re in your timezone, understand your operational constraints, and have skin in the game.

Technical Expertise: Our team isn’t just sales staff—they’re technical professionals who understand NDT applications, can specify equipment correctly, and provide meaningful support throughout the equipment lifecycle.

Transparent Pricing: No hidden fees, no surprise charges, no confusing price structures. We provide clear quotations that respect your budget constraints while reflecting the true value of Dakota’s premium equipment.

Digital Innovation: Our B2B Marketplace represents our commitment to modernizing industrial procurement—making it faster, more transparent, and more efficient for everyone involved.

Quality Systems: Our ISO certifications (9001, 14001, 45001, TS 29001) aren’t wall decorations—they’re operational frameworks ensuring consistent quality in everything we do.

Industry Trends: The Future of NDT in the Middle East

As your Dakota NDT Authorized Supplier, we’re not just selling equipment—we’re partnering with you as NDT technology evolves. Here’s where things are heading:

Digital Integration: Modern thickness gauges are becoming nodes in broader asset integrity management systems. Data flows from handheld devices to cloud-based databases, enabling real-time corrosion trending, predictive analytics, and risk-based inspection planning. Dakota’s data logging capabilities position you for this future.

Advanced Materials: As industries adopt composite materials, dissimilar metal welds, and advanced alloys, NDT equipment must evolve. Dakota’s extensive materials libraries and adjustable signal processing adapt to these challenges.

Regulatory Evolution: Inspection requirements are becoming more stringent globally. Equipment with comprehensive data logging, traceability, and documentation capabilities (like Dakota’s DL models) will increasingly be table-stakes for compliance.

Remote Operations: The push toward remote and automated inspections accelerates. While handheld NDT equipment remains essential, integration with remote monitoring systems, drones, and robotic platforms is emerging. Dakota’s open data formats facilitate this integration.

Sustainability Focus: Energy transition and sustainability goals drive demand for equipment that extends asset life, prevents failures (and resulting environmental incidents), and supports efficient maintenance strategies. Accurate NDT is fundamental to this shift.

As your Dakota NDT Representative in Oman, we’re committed to keeping you informed about these trends and ensuring your equipment investments align with future requirements, not just today’s needs.

Your Next Move: Three Simple Actions

Alright, we’ve covered a lot of ground—Dakota NDT technology, Seven Star’s capabilities, procurement processes, applications, and industry trends. Let’s bring this home with clear next steps.

Action 1: Explore Our Product Catalog

Visit our NDT section and familiarize yourself with Dakota’s product range. Check specific categories for technical details:

- Thickness Gauges for corrosion and precision measurement

- Flaw Detectors for internal defect detection

- Bolt Tension for fastener integrity

- [Transducers & Accessories](https://omansevenstar.com/product-category/ndt/

Dakota NDT Official Website

Visit the official Dakota NDT website to explore full product documentation, detailed datasheets, software updates, and official manufacturer resources for professional applications.

Letter of Authorisation

Official authorization letter confirming Seven Star LLC as an approved partner of Dakota NDT, covering sales and technical support activities in Oman.

Technical Consultation & Inquiry

Our technical team assists with product selection, specifications, applications, and quotations for Dakota NDT instruments.