Dakota NDT RX8-DL Sonic Tester – Advanced Ultrasonic Thickness Gauge

Introduction: Ultrasonic Thickness Measurement Excellence

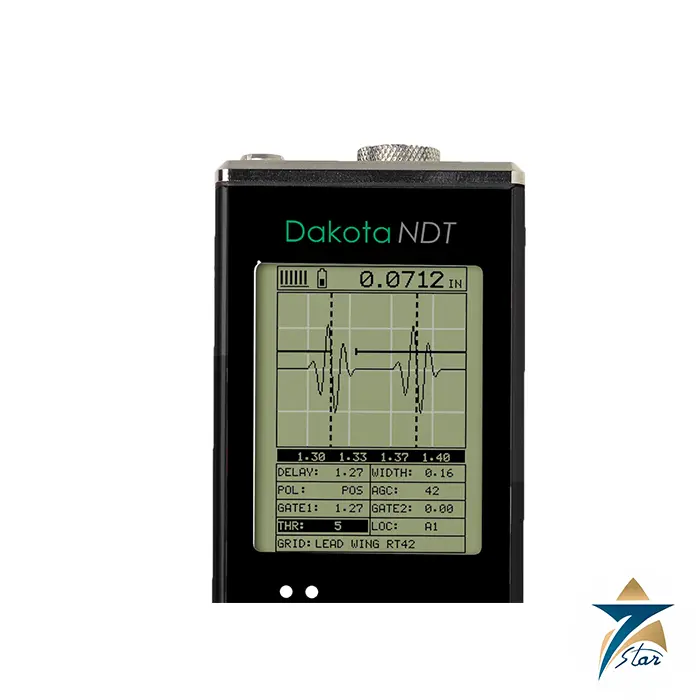

The Dakota RX8-DL Sonic Tester stands at the forefront of ultrasonic thickness testing technology, combining precision engineering with advanced digital measurement capabilities. This high-end sonic tester is especially suited for applications requiring detailed material assessment where only one surface is accessible – a hallmark of nondestructive testing (NDT) methodologies.

The RX8-DL goes beyond conventional thickness gauges by incorporating time-based B-Scan imaging, enabling users to visualize the back surface profile of the inspected part while scanning. This visual cross-section enhances interpretation, making it invaluable for engine builders, automotive specialists, and quality control engineers.

Dakota RX8-DL Sonic Tester – Instruction Manual

Dakota RX8-DL Sonic Tester (PR-8V) Datasheet

Advanced Technology & Measurement Modes

The RX8-DL uses ultrasonic pulse technology to deliver reliable thickness measurements across materials with varying compositions and surface characteristics. Its advanced features include:

-

Pulse-Echo (PE) Mode: Ideal for general thickness measurement and detection of pits, corrosion, or internal flaws.

-

Echo-Echo (EE) Mode: Designed to measure through coatings (e.g., paint) by eliminating surface coating errors and focusing on the true material thickness – crucial for coated chassis tubing and similar applications.

-

Dual-Element Transducer: Operates within a frequency range of 1–10 MHz, offering high fidelity on curved, tubular, and complex surfaces.

-

High-Speed Scan: Variable scan rate from 10 Hz to 200 Hz, allowing rapid surface inspection and automatic detection of minimum thickness points during sweep scanning.

-

Time-Based B-Scan: Provides a dynamic cross-section display that reveals internal contours, especially useful when measuring cylinder walls or engine components.

Display & Visualization

The RX8-DL features a high-resolution 1/8″ VGA grayscale display (240 × 160 pixels) that supports multiple views:

-

Large Digit View: Standard thickness readout.

-

B-Scan View: Time-based cross-section imaging.

-

Scan Bar & Stability Indicators: Real-time visual feedback on measurement consistency.

-

Selectable Units: Display thickness in millimeters (mm) or inches (in).

-

LED Backlight: Adjustable for varying lighting conditions.

Memory, Logging & Data Reporting

To support thorough inspection documentation, the RX8-DL includes a built-in data logger capable of storing custom setups, alpha-numeric files, and cylinder mapping data. The device can capture and store thickness profiles and graphical B-Scan data, which can later be transferred to PC software for reporting, analysis, and archival.

Calibration & Precision

Achieving precise results across varying materials and conditions, the RX8-DL offers multiple calibration options:

-

Single Point Calibration

-

Two Point Calibration

-

Material Selection Calibration

-

Velocity (Speed of Sound) Calibration

Factory calibration is traceable to NIST (National Institute of Standards and Technology) and MIL-STD-45662A standards, ensuring accuracy and reliability in professional inspection environments.

Technical Specifications

-

Model: RX8-DL Sonic Tester (Part Number: Z-158-0004)

-

Measurement Range:

-

Pulse-Echo (PE): 0.63 – 914.4 mm (0.025 – 36.00″)

-

Echo-Echo (EE): 2.54 – 101.6 mm (0.100 – 4.00″)

-

-

Resolution: ±0.01 mm (±0.001″)

-

Velocity Range: 305 – 18,542 m/s (0.012 – 0.7300 in/µs)

-

Pulser: 150 V square wave

-

Gain Control: Manual/Automatic Gain Control (AGC) up to 50 dB

-

Operating Temperature: −10 °C to 60 °C (14 °F to 140 °F)

-

Power Supply: 3 × AA batteries or USB power

-

Battery Life: Alkaline ~35 hrs, NiCad ~10 hrs, Ni-MH ~35 hrs

-

Weight: ~383 g (13.5 oz) including batteries

-

Dimensions: 63.5 × 165 × 31.5 mm (2.5 × 6.5 × 1.24″)

-

Packing List: Unit, standard transducer, couplant, manual, carrying case, AA batteries, PC engine mapping software & transfer cable

Industrial & Racing Applications

The RX8-DL Sonic Tester is optimized for high-precision thickness measurement in demanding professional settings:

-

Engine Cylinder Walls & Head Ports: For engine building and performance tuning.

-

Chassis Tubing & Roll Cages: Accurate measurement even through paint or coatings.

-

Body Panels & Windshields: Thickness evaluation in automotive repair and fabrication.

-

Flaw & Corrosion Detection: Using pulse-echo mode to identify pits and thinning areas.

Installation & Operation Insights

Simple to deploy in field or workshop environments, the RX8-DL is a handheld ultrasonic tester that integrates easily with PC software for advanced reporting. Operators can select preferred display modes and calibration settings to match specific material conditions. Standard dual element probes support a variety of inspection challenges.

FAQ

What distinguishes the Dakota RX8-DL from other thickness gauges?

The RX8-DL uniquely combines time-based B-Scan visualization with high-speed scanning (up to 200 Hz) and advanced calibration options, delivering both visual cross-section feedback and precision measurement.

What materials can the RX8-DL measure?

It measures metals, composites, tubing, and coated materials — including chassis parts and body panels — with dual-element transducer versatility.

Is the RX8-DL suitable for engines and racing applications?

Yes — it’s designed for cylinder walls, head ports, and engine components in racing and automotive inspection.

Does it work through coatings like paint?

Yes — the Echo-Echo mode enables thickness measurement through coatings by eliminating surface coating errors.

Can the RX8-DL log data for reporting?

Yes — it features internal data logging with customizable setups, engine maps, and alpha-numeric storage.

Is factory calibration traceable to standards?

Yes — calibration is traceable to NIST and MIL-STD-45662A for professional measurement accuracy.

Call to Action

Request a quote for the Dakota RX8-DL Sonic Tester to elevate your ultrasonic thickness measurement and nondestructive testing capabilities. Contact Seven Star LLC for pricing, availability, accessories, and technical support.

Dakota NDT is a specialist supplier of advanced nondestructive testing equipment including ultrasonic thickness gauges, flaw detection systems, bolt-tension and load monitoring devices. Its products are designed for critical inspection tasks in oil & gas, power generation, manufacturing and infrastructure projects, where accuracy, reliability and speed are paramount. With a diverse portfolio covering handheld, bench-top and wireless solutions, Dakota NDT supports operators in meeting rigorous standards and shortening inspection cycles. Through our representation in the GCC and Middle East via Seven Star LLC, customers gain direct access to genuine Dakota NDT instrumentation and local support.

Click to view complete Dakota NDT information.

Reviews

There are no reviews yet.