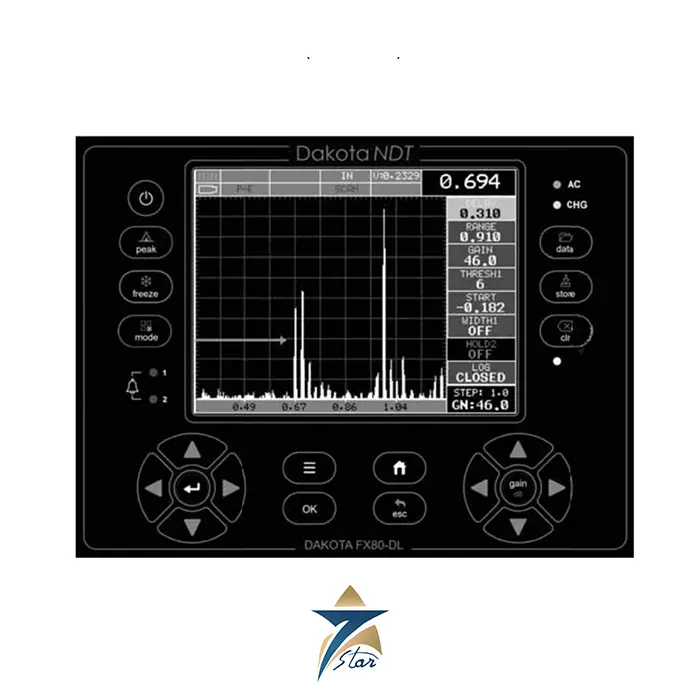

Dakota FX80-DL Bench-Top Ultrasonic Flaw Detector

Overview

The Dakota FX80-DL Bench-Top Ultrasonic Flaw Detector is a stationary ultrasonic inspection system developed for flaw detection, weld evaluation, and material inspection in controlled environments. It is designed for laboratories, fabrication workshops, and quality control departments where measurement stability, repeatability, and extended inspection sessions are required. The FX80-DL offers a reliable bench-top platform for routine and standardized ultrasonic testing procedures.

The instrument is based on Dakota’s proven ultrasonic inspection technology and provides a stable operating platform compared to handheld devices. Its bench-top form factor reduces operator variability and improves consistency of inspection results, making it suitable for comparative testing, training applications, and production quality assurance.

Dakota FX80-DL Flaw Detector (DFX-8) – Thickness Instruction Manual

Dakota FX80-DL Flaw Detector (DFX-8) – Flaw Instruction Manual

Ultrasonic Technology & Inspection Modes

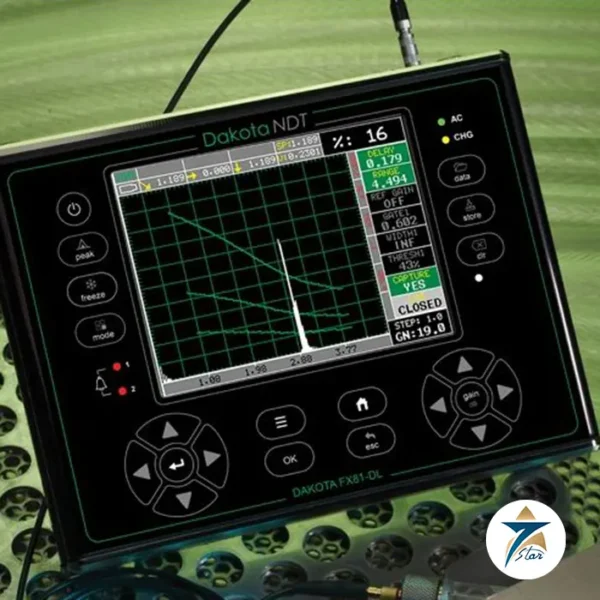

The Dakota FX80-DL utilizes ultrasonic pulse-echo technology to detect internal flaws such as cracks, voids, inclusions, and lack of fusion in metallic components. It provides real-time A-Scan waveform display for accurate signal interpretation and defect evaluation. Adjustable ultrasonic parameters such as gain, velocity, and inspection range allow optimization for different materials, probe types, and testing procedures.

The stationary configuration of the FX80-DL ensures stable signal performance during long inspection cycles and repeated measurements, which is particularly beneficial for laboratory testing and quality control inspections.

Data Logging & Inspection Workflow

The FX80-DL includes internal data logging capability, enabling storage of inspection data and measurement results during testing. Logged data can be reviewed for analysis, documentation, and reporting purposes, supporting traceability and quality management requirements. This functionality makes the FX80-DL suitable for inspection documentation, certification processes, and training environments.

Industrial Applications

The Dakota FX80-DL Bench-Top Ultrasonic Flaw Detector is commonly used in NDT laboratories, manufacturing quality control departments, and fabrication workshops. Typical applications include weld inspection, defect detection in fabricated components, inspection of test samples, and evaluation of structural materials. It is widely used in industries such as oil and gas, power generation, manufacturing, heavy fabrication, and industrial services.

Installation & Use Notes

The FX80-DL is intended for fixed bench-top installation in controlled environments. Proper ultrasonic probe selection and the use of a suitable couplant are required to achieve optimal inspection results. The stable bench-top setup improves measurement repeatability compared to handheld instruments. The system is compatible with standard ultrasonic flaw detection probes commonly used in laboratory and workshop NDT applications.

FAQ

What type of inspections is the FX80-DL designed for?

The FX80-DL is designed for ultrasonic flaw detection, weld inspection, and material evaluation in laboratory and workshop environments.

Does the FX80-DL support A-Scan inspection?

Yes, it provides real-time A-Scan waveform display for standard ultrasonic flaw detection.

Is the FX80-DL suitable for continuous inspection work?

Yes, it is designed for stationary use and extended inspection sessions.

Can inspection data be stored for documentation?

Yes, the instrument includes data logging for storing inspection results.

Who should use the FX80-DL?

It is ideal for NDT laboratories, quality control departments, and training facilities requiring stable and repeatable ultrasonic testing.

Call to Action

For technical selection, application support, or quotations, contact Seven Star LLC for supply and support across Oman and the Middle East.

Dakota NDT is a specialist supplier of advanced nondestructive testing equipment including ultrasonic thickness gauges, flaw detection systems, bolt-tension and load monitoring devices. Its products are designed for critical inspection tasks in oil & gas, power generation, manufacturing and infrastructure projects, where accuracy, reliability and speed are paramount. With a diverse portfolio covering handheld, bench-top and wireless solutions, Dakota NDT supports operators in meeting rigorous standards and shortening inspection cycles. Through our representation in the GCC and Middle East via Seven Star LLC, customers gain direct access to genuine Dakota NDT instrumentation and local support.

Click to view complete Dakota NDT information.

Reviews

There are no reviews yet.